The kind of the fuel produced: liquid (kind of masut) and solid briquetting.

Operation mode: semi-automatic.

The productivity of the plant: 500 kg of the liquid fuel and 500 kg of the solid fuel.

The capacity of the raw material bunker - 4 m3.

The number of bunkers - 2.

The size of raw material fraction used for the processing - Зmillimeters.

The size of particle in the liquid fuel - not more than 5 micromicron.

The capacity of processing plants - 500 litres.

The volume for storage - 1500 litres.

The percentage of the coal suspension composition - 50/50 ± 20 % (water, coal).

The percentage of the liquid fuel composition:

- 40 % - peat-coal paste;

- 40 % - coal suspension;

-

20 % - oil.

The percentage of peat-coal briquette composition:

- 35 % - coal;

- 35 % - peat;

- 20 % - peat-coal paste;

- 10 % - liquid fuel.

The temperature by the process of briquettes drying 120°C. The humidity of briquettes after drying not more than 40 %. The duration of the process of drying - 1,5 hours. The fuel consumption during the process of drying is 20 kg per hour.

I. The purpose and the principle of operation

1. Plant is designed to produce new kinds of fuel using traditional sources of raw materials - coal, peat, oil or masut with new characteristics in the form of peat-coal briquettes and liquid fuel.

The basis of the suggested technology is in a deep processing of wastes of fuel extraction and attaching new characteristics which satisfy standards.

As a raw material the peat and waste of coal mining are used. Oil and masut are used as modifiers. The suggested plant solves the problem of using the technology of raw materials processing in industry.

In the project there are taken into consideration the posibility of plant scaling according its productivity, power inputs, transporting characteristics, automation and the end product quality control.

2. The present plant produce 2 kinds of fuel - peat-coal briquettes and liquid fuel (kind of masut). Since both kinds of fuel have similar composition and differ only in the receipt, it allows to combine their execution in one composite plant.

On the basis of the plant process flowsheet, there have been designed a system of mechanisms which are necessary for the realisation of technological limits in the process of getting the end product.

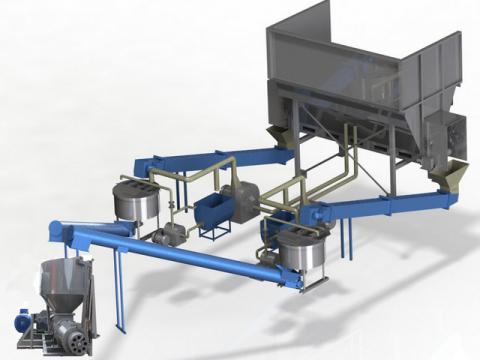

The plant is built according to a bloc sceme. Auger feeders and shelf conveyers (by loading and discharge of the drying oven) have the function of transfers between blocs. The suggested plant consists of 4 major units:

- unit of the raw material preparation which serves to store and process raw materials (crushing and fragmentation);

- unit of processing serves to get liquid components of the fuel and the liquid furl itself, and to store it;

- unit of pressing serves to dose and mix the peat-coal mass, and to press fuel briquettes;

-

unit of drying and the drying oven are used for the drying of the solid fuel according to the necessary technology, the produced liquid fuel will heat the air.

3. The general configuration of the plant is one of variants suggested for the development but not the only one. Design features are:

- the possibility the wares production either simultaneously or separately;

- units can be changed for repair in the process of the plant (working the partial doubling of major processing units);

- the maximum of automatic machinery can be used on all production stages;

- material consumption is minimum due to the quality of used products;

- the plant should be used in two-shift operation during a year, i.e. 3500 hours;

-

the routine maintenance of the plant cand be done during plant installation (the rinse of pipe-installation systems and plants, and the collection and cleaning of production wastes).

All the insallation diagrams mentioned below are basis by elaboration. If the author suggests another constructional solution with plant functionality preserving, it should be agreed with the customer.

1. Unit of raw material preparation consists of 2 major aggregates: 2 bunkers for the store of coal and peat, the crusher for peat and 2 built-in auger feeders for raw materials supply in the bolting machine, where the raw material is devided into fractions.

а) bunkers are made on one common chassis and can be drawn up and down to load bunkers with the help of a dump truck or a loader. Bunkers are supplied with winches to load bunkers and to lift the bunker cover. Inseide the bunker there are an auger feeder and 2 rippers (to prevent the raw material hanging).

There is a knife crusher on the peat batcher outlet for crushing large-scale particles in the peat.. The coal crusher is not included in the suggested plant, it should either be placed before the bunker or crushed raw material should be used.

The bunker's capacity - 4. The feeding of one butcher is not less than 5000 kg per hour.

б) the bolting machine consists of a chassis which is enclosed in the body of the plant and on which there are placed 2 cylindrical botlers with a circumferential mechanism and a belt auger which delivers materials by axle of the botler. Under every botler there are placed 2 auger feeders for large and small fraction fines. Augers for large-scale fraction are used only by the production of liquid fuel.

The bolters and its augers driving is done from one engine through an impulse reducer, a crank mechanism and a chain-drive. Batchers have their own driving gears - the engine and the planetary reducer.

The size of particles is adjusted by botler cells which have the angle of axle slope of 15 degrees. It allows to have the deeper separation of small fraction.

The productivity of botlers and batchers should agree with the common productivity of the line, i.e. 500 kg per hour for every kind of raw material.

The small fraction is delivered in the unit of processing and the large-scale fraction - in the unit of pressing. The automatic machinery should keep all branches of the unit of raw material processing running according to the operating mode of the whole plant.

2. Unit of processing consists of a chassis where processing aggregates with a mechanism for blending are situated, reservoirs for the storage and consumption of components, and an operating floor.

Reservoirs for the storage of oil, liquid fuel and peat paste are supplied with centrifugal pumps.

Processing aggregates, cavitators are the mechanisms that process the raw material with the help of an artificially made cavitation field.

Reservoirs and aggregates are connected with one another by pipe-installation systems with valves with remote control.

Reservoirs of the processing aggregates have weight sensor and the sensor of the limit level.

Reservoirs, pipe-installations and aggregates of the unit are equipped with the system for rinse in case of long suspension of production and evacuation of rinse water. For this there are pumps which rinse automatically. The rinse water is brought right to reservoirs.

The following order of aggregate loading and switching on should be kept during the coal processing. The reservoir is filled half of the processed composition's weight, the cavitator is switched on, then gradually the coal is added till the complete filling. The duration of the processing depends on the quality of the produced suspension which is check according to the size of particles (not more than 5 micromicron) and relative density of the suspension -1,2kg per cubic decimeter.

During the peat processing the order dependes on the receipt but solid components should be loaded gradually and after all others. Quantative characteristics can be changed depending on receipt and the humidity of peat. The quality of the produced peat paste is checked by an quality inspection tool. That detrmines the duration of processing.

The aggregate for the production of liquid fuel can work with any order of filling but with keeping the weight dosage according to the receipt. The quality of the fuel is checked by the homogeneity of the produced fuel. The products of processing (paste, liquid fuel) are delivered in storage volumes.

All reservoirs have technological covers for cleaning the reservoirs during repairs.

Reservoirs for the storage have the capacity of 1500 litres, reservoirs for the processing - 700 litres.

3. Unit of pressing represents the complex of aggregates and instruments combined into one unit. The complex of pressing unit consists of 2 weight automatic proportioner with continuous action and 2 liquid proportioners. All proportioners have the adjustment range which is 50 % of the rating value.

The press-blender represents an impeller mixer with continuous action and a conical expeller (an auger press machine) which are placed on a common carcass and have a common driving gear in the form of a reducer and an engine.

The blender represents a double-seat arbor with variable vanes which allow to adjust the material supply coordinating it with press supply during adjustment and alignment. The body of the blender should allow to perform these operations quickly, i.e. they should be quick-dismountable or equipped with structural access doors.

The conical expeller should compact the mass with the exertion of 80-100 kg per centimeter and form the peat-coal blend into briquettes of 40 millimeters across diameter and 100-150 millimeters length.

The press molding nazzle can have several outles, the total area of which should be equal to the area of the outlet of the press or should have the area which is gradually increasing by 10-15 %, that is the condition for the quality of the briquette surface. The nazzle should be easily removed and installed on the press. It is advisable to have changeable nazzles with other outlet cut but with same area proportion.

The productivity ot the unit of press should be in 25-30% greater and be not less than 700 kg per hour of the raw mass.

On the outlet there is a slanting delivery tray (the length - not less than 1000 m), from which briquettes by gravity are delivered into a belt drag slanting conveyor of the drying oven charging. In the upper part of the conveyor there has benn designed a rotary choke to close the inlet of the drying oven. The choke is set in motion by conveyor blades.

The width of the conveyor - 900 millimeteres. The angle of inclination and its length are determined taking into consideration the construction and location of the drying oven. The rate of the belt movement is adjusted with the productivity of the press and the productivity of the drying oven. The similar conveyor is used by the charging of briquettes from the drying oven, with the only difference that the gate-type choke is situated at the bottom of the conveyor and closes the lower outlet from the drying oven.

4. The drying oven represents the complex of aggregates and instruments for the drying of peat-coal briquettes at the temperature of 120° С during 1,5 hours. The briquette should have the humidity of 30° С after being dried in the drying oven. The upper temperature limit in the drying oven is 120° С, it is limitted because of conditions of briquettes inflammation. Briquettes are dried with the help of hot air comming from a heat exchanger.

The drying oven consists of 3 major aggregates: the drying oven itself, the heat exchanger and the combustion chamber which operates on liquid fuel.

The body of the drying oven represents a closed reservoir in the form of a cylinder with 2 walls; the superior envelope serves as a heat-shield and a directing encasement for the cold air, and the heat exchanger where the cold air is preliminarily heated from the inside of the body. In the interior of the drying ovent there is a spiral perforated gutter which has the pulsed circumferential movement. Due to it briquettes can move in the gutter from the top to the buttom. The rate of briquettes movement is determined by the duration of the process of drying and is given by the angle of the gutter and the frequency of the pulsed movement, and comprises 0,008 metres per second. The angle of inclination is 2, frequency - 1 hertz, amplitude - 8 millimeteres.

The movement of the air through the heat exchanger and the drying oven is carried out by the ventilator which is placed separately from the drying oven and which creates a reduced pressure in the whole system.

The scheme of the system is:

atmosphere (medium) - encasement - heat exchanger - drying oven - cyclone - ventilator - atmosphere.

The air emissions are used for the heating of the accomodation due to its high temperature (about 100°С). The exchange of air in the drying oven comprises 300 times per hour, that allows to dry briquettes. For this the ventilator № 6 is installed (the productivity - 500, the engine capacity - 4 kilowatt).

Briquettes in the drying oven are moved towards the stream of air. The gutter is set in motion by the mechanism of agitation and the mechanism of pulsation. The mechanism of agitation works only in emergency, when briquettes get stuck somewhere in the gutter. The total area of the gutter is 70 m , the ttal capacity (1 row) - 1500 kg.

The drying oven bears up against a build-in tubular double-flow heat exchanger and then there is the drying oven itself. The temperature is adjusted by a temperature-sensing device and fixed on a tape. The temperature deflection should not be more than 10°С from the given 120°С. The temperature adjustment is done by the changing of the quantity of the fuel in the drying oven and by the adjustment of the cold air supply in the blending machine before the heat exchanger.

The combustion chamber serves to heat the air by the products of combustion and supply the heat exchanger with hot gases. The total quantity of heat necessary for the air heating comprises 180000 kilocalories per hour; the fuel consumption to get that quantity of heat is 20 kg per hour, the fuel caloricity - 9000 kilocalories per kilogram.

The combustion chamber is made from fire bricks stown into a metal body. The chamber has 2 atomizer for the main fuel, which is produced on the suggested plant, and for the illumination fuel (oil), depending on the selected kind of the atomizer there can be installed additional high-pressure pumps.

The adjustment of the supply of the fuel in atomizers is done automatically depending on the temperature of the air in the drying oven.

Used gases after the heat exchanger are exhausted in the atmosphere by a smoke exhauster.

Dried briquettes are dilivered by the conveyer in the bunker of the end product with the capacity not less than 15m, the bunker is unloaded into the transport.

Productivity - 4 tonns per hour х 3 = 12 tonns per hour.

Volume of processed material - 4224 tonns per month.

End product - 50 688 tonns per year.

Production area - 300 square metres.

Area of storage facilities - 500 square metres.

Maintenance staff - 30.

Electric energy demand (per month) - 900 megawatt.