General characteristics of the technology

Table of using the rubber crumb

The problem of the environmental safety is becoming more and more acute in our modern society. As a result, to protect the environment huge amounts of investment are being made for restructuring the industrial process. The best way-out is designing a closed production cycle where no harmful wastes can escape, and the end product can be processed and used again. Existing technologies of processing allow to utilize practically any wastes of human vital functions. But for the successful realization of these technologies the end process of the utilization should be profitable in accordance with laws of the economics.

General characteristics of technology

Damped tyres can be classified as a compound type of industrial wastes. They do not do the direct damage to the human health but they are resistant to different actions. They are not autodestractive and the problem of their profitable processing is still unsolved. As a result tyres are being collected on town dumps. At the same time on practice these dumps represent a danger to a man. The fire originated on such dumps is capable of causing pollution, moreover it is extremely difficult to put out such a fire and it can last for years. The areas of dumps represent the hotbeds for reproduction and evolution of different insects – carriers of diseases. The usage of the land for dumps itself costs money and can cripple the environment. In Germany alone 81000000 used tyre-covers (about 600 000 tons) are being withdrawn from circulation per a year. Taking into consideration that 1 ton of tyre-covers occupy about 15 m3 the general volume of dumps makes up in average 9 000 000 m3.

To solve this problem the German government provide the organizations which are engaged in the recycling of tyres, with the subsidy. Similar actions are made in other countries of West and East Europe. In Russia the allocation of subsidies depends on regional authorities who receive subsidies by imposing different obligations and instructions on users and producers (spreaders) of tyres. Despite all actions the problem of used tyres remains urgent in the world, confirming the fact that the profitable technology of the tyre recycling is still to be found.

The most promising method of the tyre utilization is the mechanical pounding of tyres. The end product of this processing is the rubber powder or crumb. Many methods of the tyre pounding have been worked out but as a rule they all are power-consuming and capital-intensive that cause the high prime cost of the rubber powder. The method with preliminarily cooling and extra chemical acts doesn’t substantially reduce the prime cost, but the end product is of the lower quality and sometimes doesn’t serve for practical usage.

The basic indicators of the quality of the rubber powder is the chemical purity, “activity”, form and size of particles. Such powder is successfully used in the manufacturing of reclaim in elastic industry, civil engineering, paving, for the production of supports and flexible plastic, in all cases when the end product should be flexible, soundproof and sorbing. The major obstacle for the broader application of the rubber powder is its high prime cost, as long as to produce 1 ton of the fine-dispersed rubber powder with the help of existing technologies 1000 kilowatt of electrical energy is spent.

The problem of the damped tyre processing is determined by the technology profitableness and quality of the produced products of the processing, because the materials produced from damped tyres (rubber powder, woven and metal cord) are expensive products.

Nowadays both abroad and in Russia there are being worked out different complexes for the processing of damped tyres into the powder or crumb of different quality and expenses for its production. They are also different in their productivity. However, the thorough analysis shows that in the sum of basic parameters all the existing solutions are non efficient, and the quality of the end products is low for all that the price is high. It means that the processing of damped tyres using the known equipment is still non profitable.

Fundamentally new approach to the process of destruction and pounding has been developed by us in Soviet Department of the Russian Academy of Science. On the basis of this approach there has been built up the unique resources-economy complex of mechanisms and technologies for the wide range of purposes. The complex contains know-how and has high competitive ability on the market. There also have been worked out effective and multi-purpose installations of the new generation for processing materials with different characteristics into the powder, pastes and suspensions. They are all economical, compact, easy and secure in use. The machinery has high specific productivity and low power inputs, it is universal and can be easily reset. It also allows to produce the output of high quality and in technical parameters it excels all existing analogues. The complex gives the opportunity for the development of new technological operations of pounding and disintegration, for the fundamental improvement of the existing processes of fragmentation and pounding, and above all for the processing of malleable-plastic and elastically malleable materials, such as fibrous materials, polymers, rubber and clay.

Besides, as a result of researches of many years there have been worked out simple and effective vortical aerodynamical separators, normalizers and classifiers which allow to separate and classify materials of the wide range of sizes (from grainy and free-flowing up to micron powders) and qualities, including powders of viscoelastic and viscous-plastic materials such as soybean flour, polymers and rubbers.

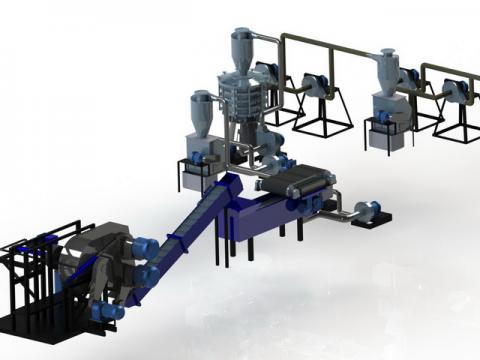

On this science-technical basis there has been made the line of the profound processing of damped tyres of any configuration into a dispersed rubber powder of high quality with the branch of textile and metal cord, and the line of producing the coarsely dispersed powder (crumb) for the road building and production of building materials.

Our complex consumes only 300 kilowatt of energy for 1 ton of the initial raw, it weights about 5 tons, and the rubber powder can be pounded up to 200 micromicrons.

Description of the complex for processing of damped tyres

The technological cycle of our production process of rubber powders made of damped tyres is based on already worked out technological solutions which precisely and economically perform all given mechanical operations: fragmentation, pounding, separation of reinforcing elements and classification of rubber powders with the purpose of receiving the established assortment.

According to the suggested technology initial damped tyres in the Utilizer are processed into the crumb of 3 – 5 millimeter size containing the metal-woven cord. In the Disk-type grinder and the Blade crusher the crumb is crushed into the crumb of less than 1 millimeter size with the simultaneous separation from cord components. The cord components in the Reel magnetic and the Vortical aerodynamical separator are separated into independent end product. The rubber crumb further is pounded in Rotary-sieve mills into the powder of the established size which is divided in the Vortical aerodynamical classifier. Inner technological travels are done with the pneumatic transport.

The complex consists of 2 lines:

The 1st Line (Miniplant) of the primary fragmentation of damped tyres with the productivity of 5-10 tons per hour, which includes:

· Utilizer of the primary fragmentation of initial tyres into the crumb (3 – 5 millimeters), productivity 5 – 10 tons per hour, specific power inputs is 15 – 20 kilowatt-hour per ton.

· Trestle for the tyre accumulation and its delivery to the reception facility of the Utilizer.

· Transport system of the crumb removal.

The Line provides with:

1. Transportation and sorting of damped tyres.

2. Primary fragmentation of damped tyres into the crumb.

3. Transportation of the crumb to a warehouse.

The 1st Line of the primary fragmentation of damped tyres (The Utilizer):

· Productivity, tons per hour …………………………………………………. up to 10

· Adjusting capacity, kilowatt ……………………………………………….. 70

· Time for fragmentation of 1 tyre, sec ……………………………………… 10

· Particle size of the product after fragmentation, mm ……………………… 3 – 5

· Number of workers ……….……………………………………………….. 3

· Weight of the plant, ton …..……………………………………………….. 3,5

· Overall dimensions, m …………………………………………………….. 3х3,5х2

The Line is made in the mobile performance. There are no special requirements to production areas.

The 2nd Line of the production of the rubber powder and cord components with the productivity of 1 ton per hour, includes:

· Disk-type grinder for the fragmentation of the initial crumb of 3 – 5 millimeter size into the crumb of 1 – 2 millimeter size and the separation of the metal cord part, with power inputs of 25 – 30 kilowatt-hour per ton.

· Magnetic separator of the metal cord.

· Rotary crusher for the fragmentation of the initial crumb of 1 – 2 millimeter size into a rough powder with particles of less than 1 millimeter size, with a complete separation of the rubber from a woven cord, specific power inputs is 35 - 45 kilowatt-hour per ton.

· Vortical aerodynamical separator for the separation of a woven cord with specific power inputs 5 - 10 kilowatt-hour per ton.

· Rotary-sieve mill to receive the rubber powder of the needed dispersibility (less than 350 micromicrons) with specific power inputs of 35 - 50 kilowatt-hour per ton.

· Vortical aerodynamical classifier for the separation of the rubber powder into fractions with power inputs of 5 – 10 kilowatt-hour per ton.

· Unit of the dust and gas purification.

The Line provides with:

1. Separation of the metal cord.

2. Fragmentation of the coarse rubber crumb, separation of the woven cord.

3. Pounding of the rubber crumb.

4. Sizing of the rubber crumb.

5. Refinement of the ventilating discharge.

The 2nd Line of the production of the rubber powder and cord components:

· Productivity (end product), tons per hour ………………………………… 1

· Adjusting capacity, kilowatt ……………………………………………… 379,6

· Particle size of the producible powder (I fraction), micromicron ………… 250

· Particle size of the producible powder (II fraction), micromicron ……….. 350

· Standards of the power consumption, kilowatt …….…………………….. 277

· Number of workers (3 teams of 5 workers) ………………………………. 15

· Production areas

The major advantages of the suggested technology are the high economy of the nonchemical technological process of the profound processing of worn-out tyres, the simplicity of the basic technical means of the processing that supply the complex with the high rate of the output of the valuable fine rubber powder, alloyed metal and viscose cord in the form of a cotton-like mass.

The high effectiveness of the suggested alternative technology of the processing of utilized tyres is based on the engineering realization of our physical model of destruction by pounding in the way of the new generation of intensive alternative methods, machinery and technologies, including those for the processing of malleable-plastic materials.