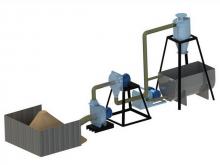

Ashes processing

Here are results of the technical and economic assessment of the technology for a deep processing of ashes in heat-electric generating plants with the emission of valuable components as marketable products.

The basis of technological solutions is comprised of results of researches done by members of the Institute "Hydrotsvetmet" and by YOUR initiative.